2D Computer Controlled Machining

2D Machining

2D machining is the use of a CNC machine to mill out a flat objects. In a way, this is similar to laser cutting, but on a large scale, from the machine used to the materials needed.

Assignment

- make (design+mill+assemble) something big

For this assignment, we were tasked on making, which included designing, milling and assembling, something large (e.g. Flat-pack furniture)

Proficiency Test

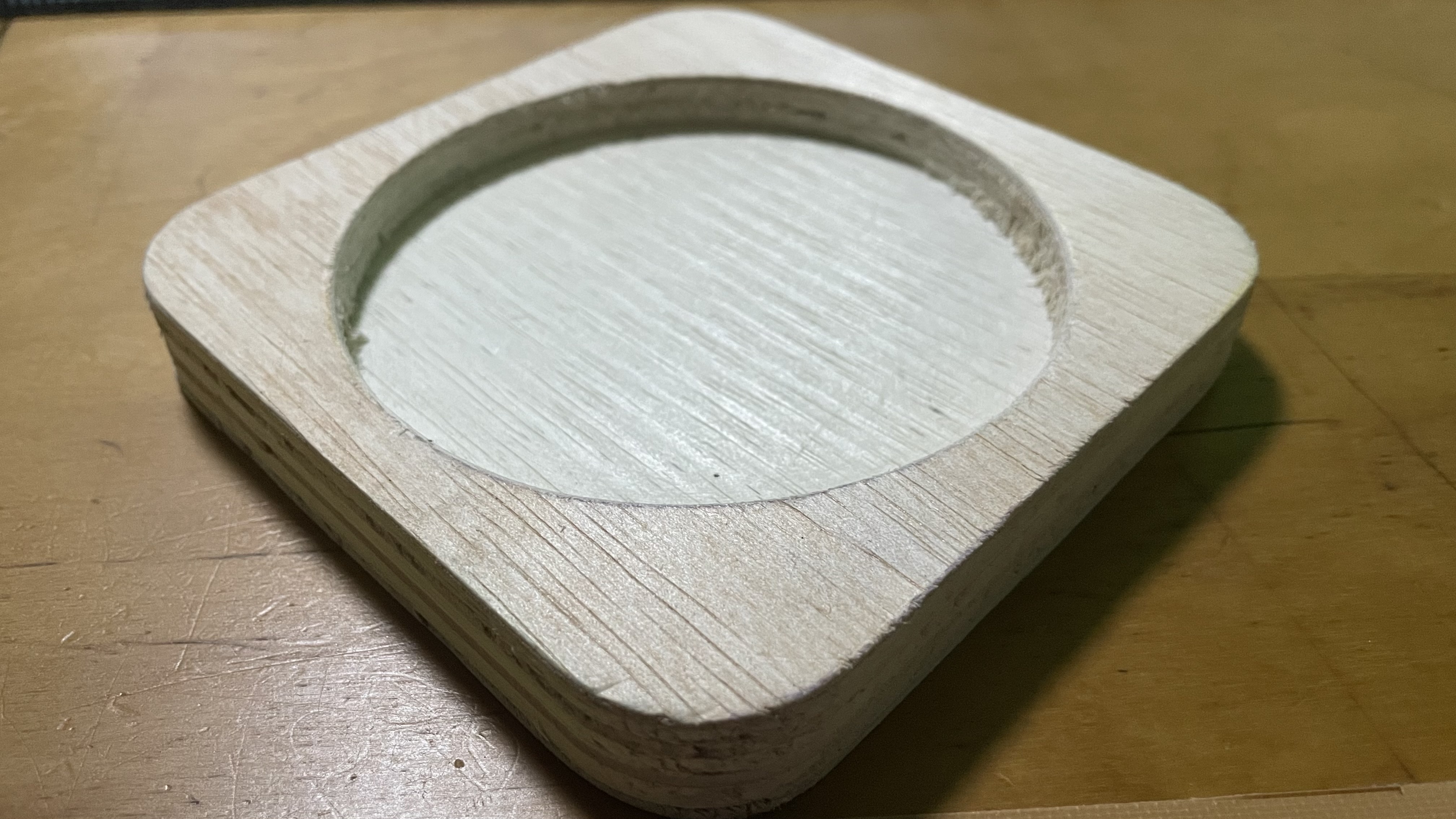

Before I could even get to work, the first thing that we had to do was to go through a proficiency test in order to see if we were capable of even operating the machinery. As the machinery being used is quite large scale, precautions had to be taken before we were allowed to use the machine for our assignments. Using a premade DXF file of a coaster provided by our lecturer, we had to use the program VCarvePro to generate out a gcode for the coaster in order for the machine (Versatil CNC 2D Router) to read it and successfully cut out the coaster. We were taught on the settings used for the cutting, the types of cutting needed for the coaster, as well as how to calibrate the machine and the material. With guidance from the lecturer, this is how the coaster turned out.

Back to the assignment

For the assignment, I decided to make a flat pack stool/footrest. After modelling it out, this is how it looked.

2D CNC

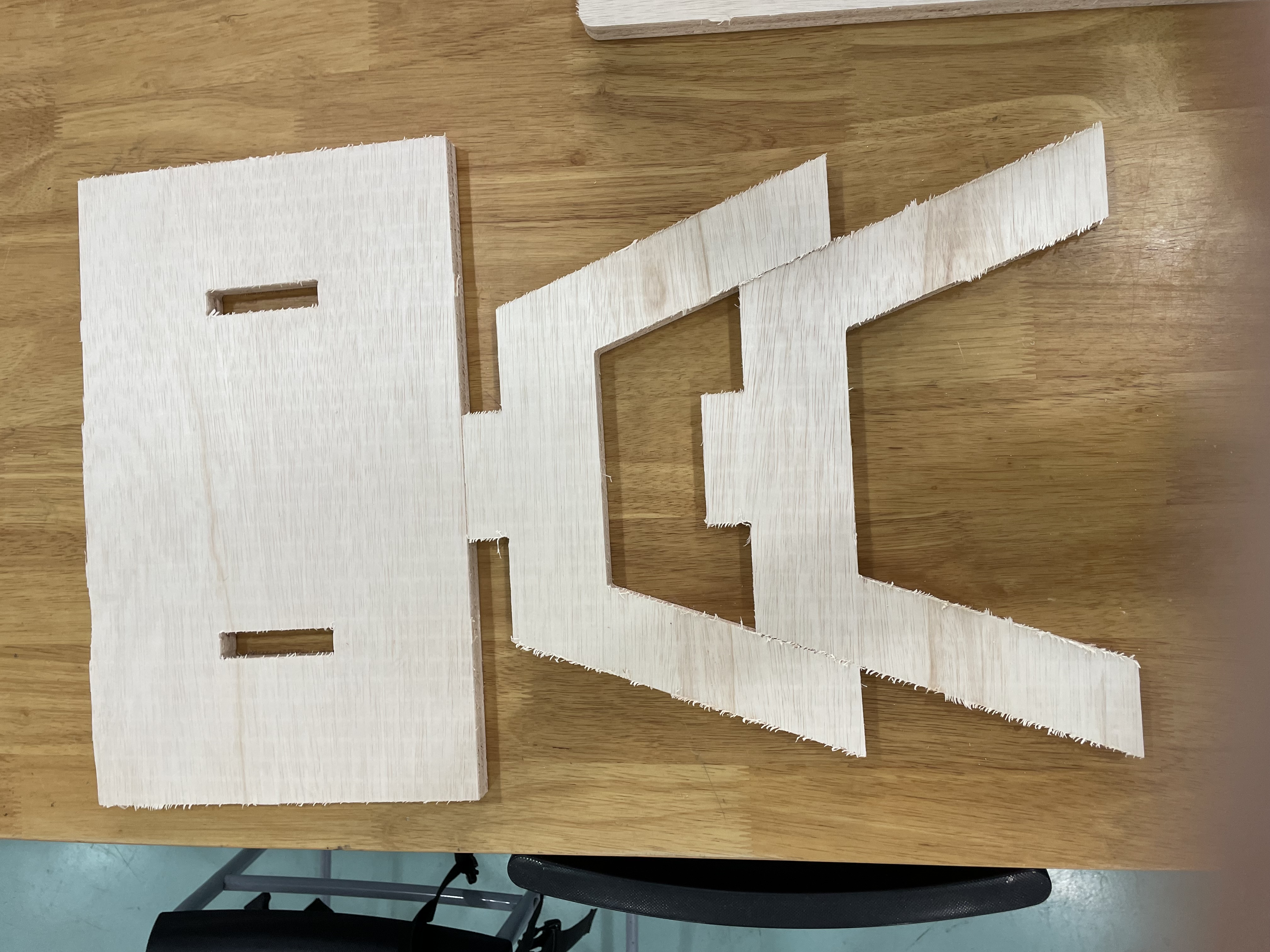

After getting my model ready, I went down to the large format CNC machine and prepared to cut out my model. The reason I had not exported the DXF File earlier was because I was unsure what thickness of wood was available at the lab, therefore I had to check the wood thickness first, make the necessary changes, then I can export the file. After confirming the thickness, I exported the file and brought it into the machine to be prepared to cut.